КАТЕГОРИИ:

АстрономияБиологияГеографияДругие языкиДругоеИнформатикаИсторияКультураЛитератураЛогикаМатематикаМедицинаМеханикаОбразованиеОхрана трудаПедагогикаПолитикаПравоПсихологияРиторикаСоциологияСпортСтроительствоТехнологияФизикаФилософияФинансыХимияЧерчениеЭкологияЭкономикаЭлектроника

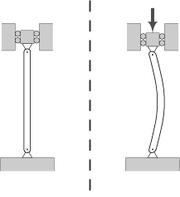

Buckling

A column under a centric axial load exhibiting the characteristic deformation of buckling.

A column under a centric axial load exhibiting the characteristic deformation of buckling.

When subjected to compressive forces it is possible for structural elements to deform significantly due to the destabilising effect of that load. The effect can be initiated or exacerbated by possible inaccuracies in manufacture or construction.

Lateral-torsional buckling of an aluminium alloy plate girder designed and built by students at Imperial College London.

Lateral-torsional buckling of an aluminium alloy plate girder designed and built by students at Imperial College London.

The Euler buckling formula defines the axial compression force which will cause a strut (or column) to fail in buckling.

where

F = maximum or critical force (vertical load on column),

E = modulus of elasticity,

I = area moment of inertia, or second moment of area

l = unsupported length of column,

K = column effective length factor, whose value depends on the conditions of end support of the column, as follows.

For both ends pinned (hinged, free to rotate), K = 1.0.

For both ends fixed, K = 0.50.

For one end fixed and the other end pinned,  0.70.

0.70.

For one end fixed and the other end free to move laterally, K = 2.0. This value is sometimes expressed for design purposes as a critical buckling stress.

where

σ = maximum or critical stress

r = the least radius of gyration of the cross section

Other forms of buckling include lateral torsional buckling, where the compression flange of a beam in bending will buckle, and buckling of plate elements in plate girders due to compression in the plane of the plate.

Materials

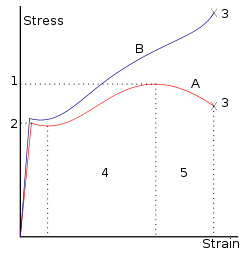

Stress-strain curve for low-carbon steel. Hooke's law (see above) is only valid for the portion of the curve between the origin and the yield point.

1. Ultimate strength

2. Yield strength-corresponds to yield point.

3. Rupture

4. Strain hardening region

5. Necking region.

A: Apparent stress (F/A0)

B: Actual stress (F/A)

Structural engineering depends on the knowledge of materials and their properties, in order to understand how different materials support and resist loads.

Common structural materials are:

Iron

Дата добавления: 2014-12-23; просмотров: 278; Мы поможем в написании вашей работы!; Нарушение авторских прав |